- Products

- Services

- News & Event

- About Us

- Career

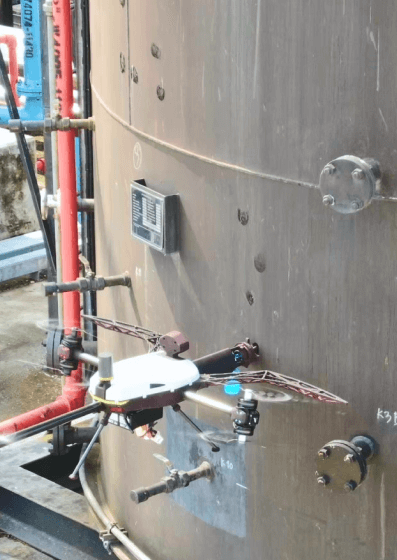

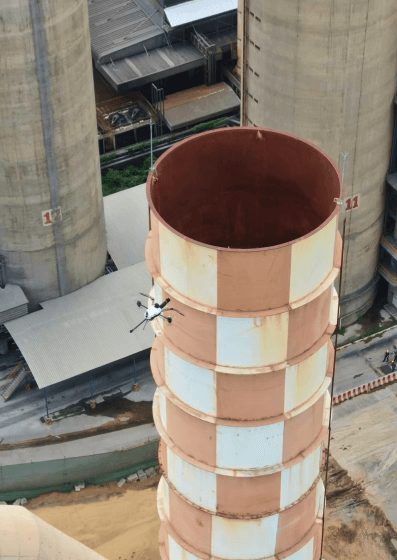

STORAGE TANK INSPECTION

Skyller's Storage Tank Inspection service uses advanced drones equipped with EMAT and Ultrasonic Testing (UT) sensors to provide precise corrosion detection and thickness measurement. With no need for scaffolding, the service reduces operational risks and costs while ensuring regulatory compliance and asset integrity. This drone-powered solution captures high-quality data, offering fast and comprehensive inspections, even in hard-to-reach areas

Highlight

EMAT CORROSION DETECTION

ULTRASONIC TESTING (UT) THICKNESS MEASUREMENT

NO SCAFFOLDING REQUIRED

200 MEASUREMENTS PER HOUR

COMPREHENSIVE DIGITAL REPORTS

Other Information

Additional Services

- Aerial Corrosion Detection: Focused on detecting early signs of corrosion in elevated assets.

- Environmental Monitoring: To ensure storage tanks are operating without causing environmental harm.

Benefits

Zero Scaffolding Costs: Eliminates scaffolding needs, reducing costs and human risks. Increased Efficiency: Drones capture 200 measurements per hour, speeding up inspections. Enhanced Safety: Reduces the need for operators to work at heights. Accurate, Real-Time Data: Provides detailed, traceable reports for better decision-making. Cost and Time Savings: Faster inspections lead to reduced downtime and operational costs. Regulatory Compliance: Ensures adherence to industry standards and local reg

Use Cases